Novel Sulfur Recovery Unit

A novel process developed by Flowtech and partners aims to efficiently recover sulfur in the oil and gas production. It is based on the well known "Modified Claus Reaction Process". The proposed changes in the common process aim to reduce unwanted byproducts, energy consumption, operating costs and CO2 emissions.

As part of the design process, the basic process was validated by Flowtech by means of a three-dimensional Computational Fluid Dynamics (CFD) simulation. In-depth analysis of the process in the combustion chamber led to new insight which was fed into the optimization procedure. A realistic picture of the process was achieved by considering relevant phenomena such as combustion, sulfuric acid evaporation, chemical reaction kinetics and thermal radiation.

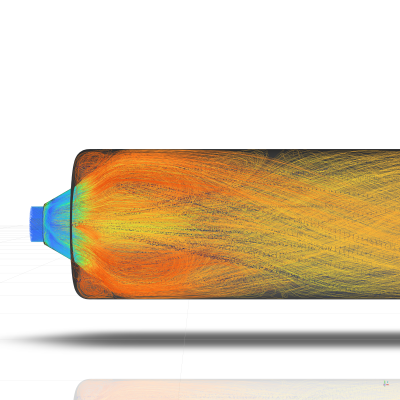

Gas temperature stream-lines and sulfuric acid spray in the combustion chamber (front view)

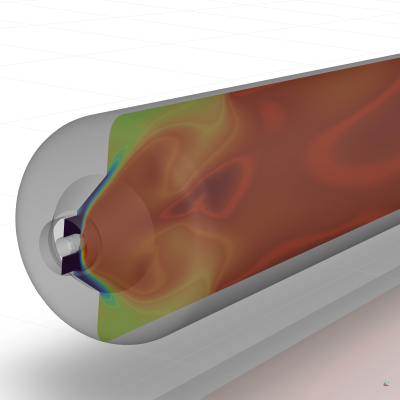

SO2 concentration in the combustion chamber

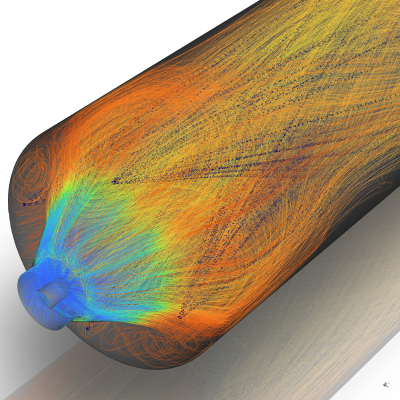

Gas temperature stream-lines and sulfuric acid spray in the combustion chamber (3-D view)

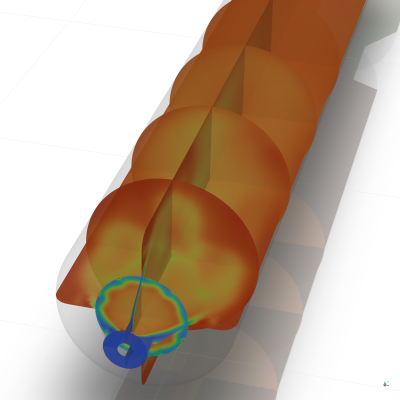

Contours of gas temperature in the combustion chamber