Fluid Dynamic Design of a COG-MgO SCR Unit

We optimized the DeNOx process of a COG-MgO SCR unit for one of our Austrian customers by means of Computational Fluid Dynamics (CFD). The goals comprised mixing the hot gases from a duct burner with colder flue gases, as well as injecting and mixing ammonia within them. We determined the optimum design, position and arrangement of the static mixers, the ammonia injection grid and the guide vanes to comply with the requirements from the catalyst supplier. The simulation additionally revealed that only half of the initially foreseen static mixing modules were required to reach the set goals. Our customer benefits now from a satisfactory DeNOx performance and a low energy consumption of the fan.

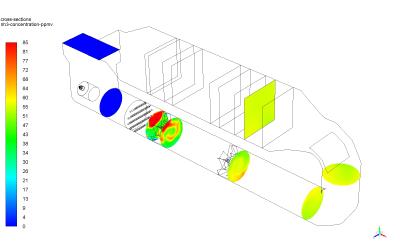

Ammonia distribution inside the SCR unit

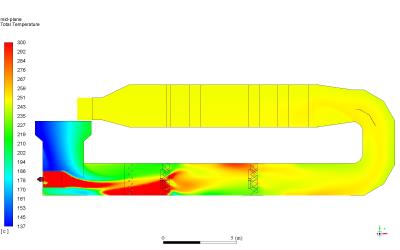

Gas temperature distribution inside the SCR unit (CFD plot)