CFD Optimization Study of the DeNOx Unit in a Cement Plant in the USA

To comply with the gas velocity, temperature and reagent distribution requirements upon the SCR reactor, several installations were recommended as an output of the simulation study. We supplied our in-house twin-fluid injection lances to atomize the ammonia-solution inside the flue gas duct. Our three-stage static mixing system (Flowte-B/-X) allowed to mix the ammonia with the flue gases, as well as the high gas temperature from several upstream burners with the colder flue gases. The short available mixing distance between the mixers and the catalyst layer was here a particular challenge.

In the mean time, our recommendations have been implemented and the plant is currently performing satisfactorily.

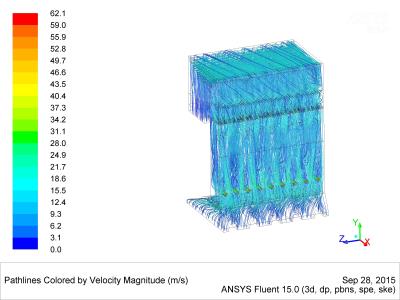

Path-lines of velocity inside the SCR unit

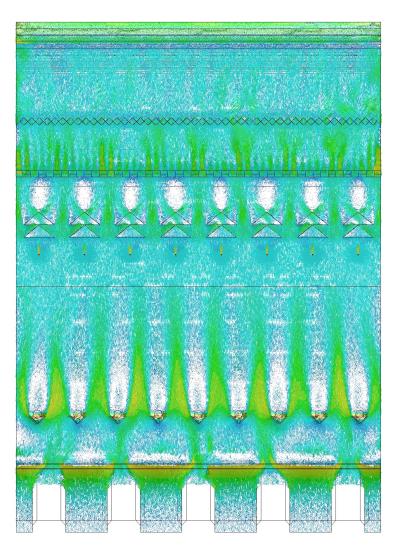

SCR unit as part of the cement plant

On-site installation of the static mixers

Ammonia-solution direct injection and mixing system (Flowte-B/-X)

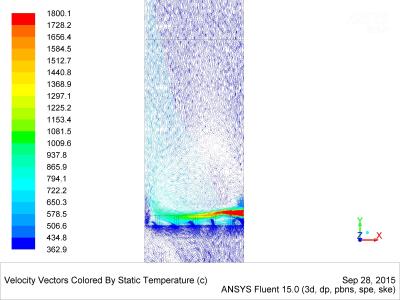

Gas burner inside the DeNOx facility (gas temperature)